OUR PRODUCTS

All of our product development revolves around customization, and our commitment to global

technology leadership assures that we are providing the greatest products possible for our devoted customers.

FORGING INGOTS & BILLETS

We produce MS Alloy Ingots ( Forging Quality ) of different EN grades and sizes as per customer demands.

Presently we are having capacity of producing 6000 MT of Forging Quality , casting one heat of 10 metric tons Material .

We had successfully casted En-8, En-9, En-18, En-19, En-24, En-42, En-111,C-25, C-40, C-42, C-45 and 55Cr70.

Following are the sizes available:-

| SI.NO | Size In Inches | Type | Approx. Wt. per Piece (kg)* | Mold Height | Hot top height |

|---|---|---|---|---|---|

| 1 | 10*12 | Square | 1300 | 75" | 9" |

| 2 | 12*14 | Square | 1700 | 75" | 9" |

| 3 | 14*16 | Square | 2300 | 75" | 9" |

| 4 | 17*19 | Fluted | 2600 | 75" | 9" |

| 5 | 19*21 | Fluted | 3200 | 75" | 9" |

| 6 | 22*24 | Fluted | 4200 | 75" | 9" |

| 7 | 25*28 | Fluted | 5200 | 75" | 9" |

| 8 | 28*33 | Fluted | 6200 | 75" | 9" |

| 9 | 30*33 | Fluted | 7150 | 75" | 9" |

We produce MS Billet/Bloom, with a wide range of section size from 100 mm x 100 mm to 250 mm x 250 mm and bloom size 280 mm x 320 mm along with BIS marked in products of IS-2830 and IS-2831. Our supplies are customized as per customer requirements. We also deliver different grades of carbon/ spring/ alloy steel products such as EN-8, EN-9, EN-18, EN-19, C-45, Sup 9 and Sup 11.

| Billets | Blooms |

|---|---|

| 100*100 | 200*200 |

| 110*110 | 200*250 |

| 125*125 | 250*250 |

| 160*160 | 280*300 |

| 160*200 | 280*320 |

| 150*340 | |

Supply Conditions

FORGING INGOTS

- Supplied in Spot Grinded or Fully Grinded Condition

- Cropped Ends

- Free from surface defects or cracks

- Ingots are supplied with smooth ends

- 100% tested through handheld spectrometer

- Marked with heat number, grade, size and weight

- Free from radioactive elements & mercury, lead contamination

BILLETS

- Suitable for Ring Rolling, Forging, Re-rolling & Up-setting.

- Maximum length up to 9 meters

- Cold Sawable

- Hard Stamped with Heat Number, Grade & Size & Weight of the Billet

- Spot Ground or Fully Ground Surface - as per the requirement

- Free from surface defects & Cracks

- Smooth ends (without burrs) / No sharp edges

- 100% material identity tested thru Niton handheld spectrometer

SPONGE IRON

Sponge iron is also known as Direct Reduced Iron (DRI), is the product of reducing iron oxide in the form of iron ore into metallic iron, below the melting point of iron and typically in the range of 800–1200 °C. Sponge iron is used in the iron and steel industry as a substitute for scrap in induction and electrical arc furnaces.

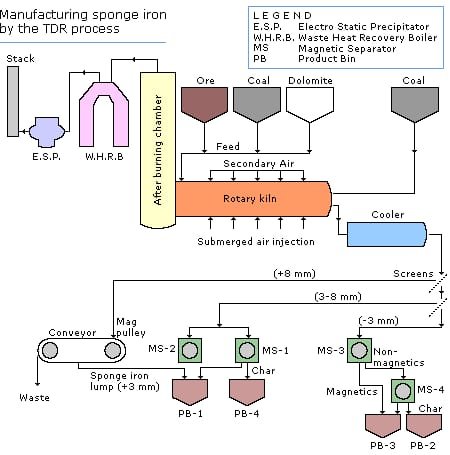

Process

Sponge iron making is a process in which iron ore lumps (5mm-18mm size) are tumbled with a ‘select’ grade of coal & dolomite inside an inclined rotary kiln and control combusted in the presence of air for about 12 hours before the products are air cooled, magnetically separated, screened and size wise in finished product bunkers prior to dispatch.

The process entails a direct reduction of the iron ore (i.e. removal of oxygen from the ore) in solid state to metalize the ore at a ‘critical’ temperature to make this possible.

The basic reduction reactions in a coal based DRI process is as follows:-

C+ O2 = CO2

CO2 +C = 2CO

3Fe2O3 + CO = 2Fe3O4 + CO2

Fe3O4 + CO = 3FeO + CO2

FeO + CO = Fe + CO2

We are manufacturing DRI in following Specifications:

| Parameters/Material | DR Clo | Pellet |

|---|---|---|

| Fe(m) | 82(+-) 1 | 80 (+-) 1 |

| Carbon | 0.15 | 0.15 |

| Sulfur | 0.035 | 0.035 |

| Size | 0-20 mm | 3-20 mm |

| -1(mm) | ‹20% | - |

Supply Conditions

FORGING INGOTS

- Supplied in Spot Grinded or Fully Grinded Condition

- Cropped Ends

- Free from surface defects or cracks

- Ingots are supplied with smooth ends

- 100% tested through handheld spectrometer

- Marked with heat number, grade, size and weight

- Free from radioactive elements & mercury, lead contamination

BILLETS

- Suitable for Ring Rolling, Forging, Re-rolling & Up-setting.

- Maximum length up to 9 meters

- Cold Sawable

- Hard Stamped with Heat Number, Grade & Size & Weight of the Billet

- Spot Ground or Fully Ground Surface - as per the requirement

- Free from surface defects & Cracks

- Smooth ends (without burrs) / No sharp edges

- 100% material identity tested thru Niton handheld spectrometer

POWER

M/s Vaswani Industries Limited has installed an 11.5 MW capacity power plant in addition to the Sponge Iron and Steel Division.

We utilize flue gas, and form steam from our 03 Waste heat recovery boilers (WHRB), in the form of renewable energy from 100 TPD sponge iron kilns. We have also installed an AFBC boiler in which a maximum amount of dolochar (By Product of DRI production) is used as fuel. The Electricity Generated in the captive power plant is used by the steel Melting shop (SMS). This process of utilizing waste heat to generate into electricity is extremely beneficial for the environment.

Supply Conditions

FORGING INGOTS

- Supplied in Spot Grinded or Fully Grinded Condition

- Cropped Ends

- Free from surface defects or cracks

- Ingots are supplied with smooth ends

- 100% tested through handheld spectrometer

- Marked with heat number, grade, size and weight

- Free from radioactive elements & mercury, lead contamination

BILLETS

- Suitable for Ring Rolling, Forging, Re-rolling & Up-setting.

- Maximum length up to 9 meters

- Cold Sawable

- Hard Stamped with Heat Number, Grade & Size & Weight of the Billet

- Spot Ground or Fully Ground Surface - as per the requirement

- Free from surface defects & Cracks

- Smooth ends (without burrs) / No sharp edges

- 100% material identity tested thru Niton handheld spectrometer

Quick Fact

Vaswani Industries Limited is the largest producer of Sponge Iron in Central India.